I bought a 10 foot board of true 8/4 Padauk and also a 12/4 board of Sapele Mahogany. I probably have enough wood to make a shamisen for me and some grandchildren shamisens. I planned to use the 12/4 Sapele to build the jig for the skin stretcher. Is that wood strong enough? It seems about half as heavy as oak but has a 1510 Janka hardness…White Oak has a Janka of 1450. I also bought a 1 inch thick narrower boards of Bubinga and Bloodwood. Would those be better to laminate onto the Padauk for a fingerboard on the neck? I bought a 1 inch thick oak board to make the skin stretching clamps…

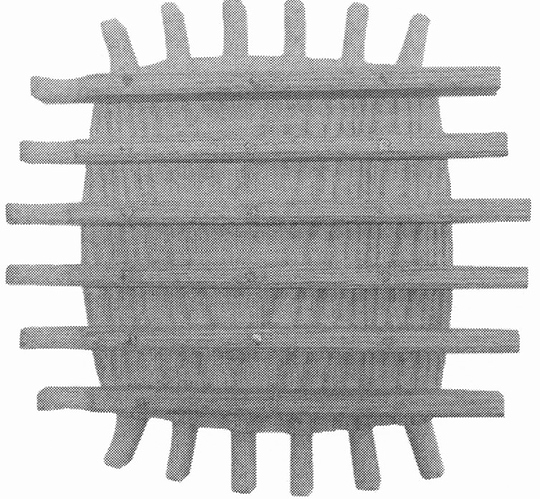

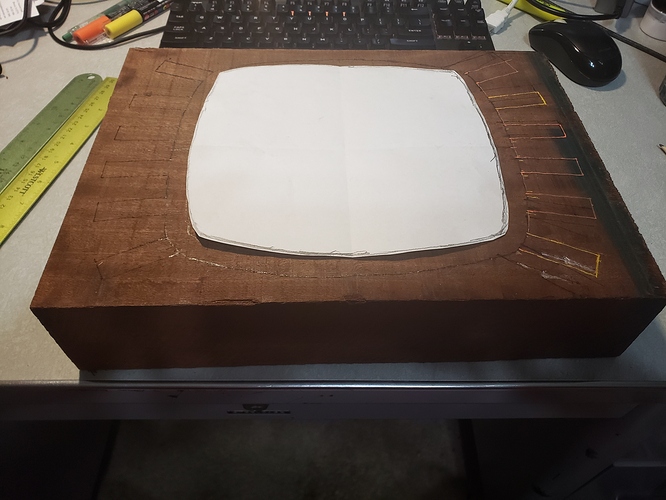

This is the Sapele 12/4 wood. It is 10 inches wide. I used a piece of paper to trace the body of the shamisen that I have for a pattern and then added a margin around that for extra wood. I used 20 mm between the fingers instead of 25 as Kyle mentions in his book. I am thinking I can buy a longer blade for my jig saw and use that to saw out the fingers of the jig. I hope I can use a jig saw to also rough saw out the other pieces of the Shamisen from the one Padauk board.

.

This is the Padauk wood that I plan to use to build one Samisen from. It is true 8/4.

This is a smaller 4/4 board of oak. I plan to make the bottom fingers for the skin stretcher and the 20 clamps out of this.